Introduction: Selection of network transformer magnetic core and enameled wire and their impact on network transformer EMC

For network transformer manufacturers, the issues in electromagnetic compatibility and electrical isolation are material selection (especially the selection of insulating materials and magnetic materials) and manufacturing process issues.

Regarding the selection of enameled wire:

According to different welding and winding processes, enameled wires with different requirements are selected. for example:

First, the direct plug-in network transformer uses wave soldering during welding. The welding temperature does not directly affect the coil, so enameled wire with a temperature resistance of 130°C is used.

Second, patch-type network transformers use reflow soldering during welding. The welding temperature directly affects the product, so enameled wire with a temperature resistance of 155°C is used.

Third, if it is a lead-free soldering process, the SMD transformer should use 180°C enameled wire.

Fourth, according to different winding processes, choose enameled wires with different voltage levels.

There are two situations: if the wire is wound on the skeleton, choose 2UEW enameled wire, which can meet the requirements of electrical isolation; if the wire is wound on the magnetic ring, choose OUEW+N-F enameled wire, which is in OUEW On top of that, a layer of nylon and Teflon materials are added. Nylon can make the surface of the enameled wire slippery, making it less likely to damage the paint during the winding process. Teflon can improve the temperature resistance, so the electrical isolation performance is also improved. can be satisfied.

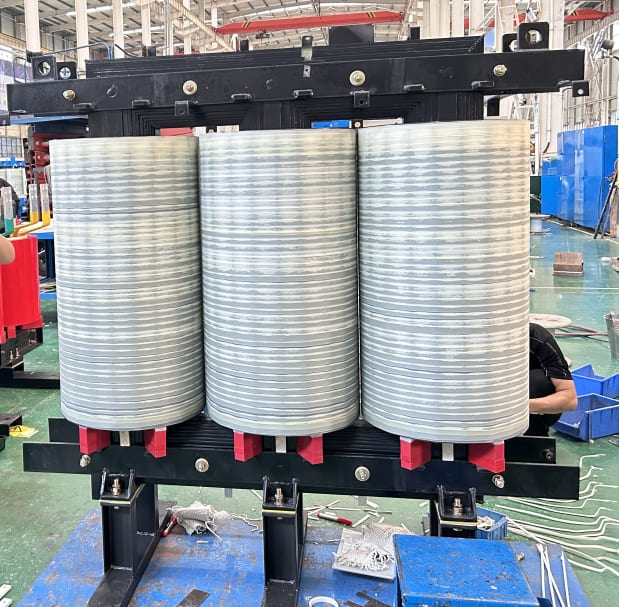

Regarding the selection of magnetic core materials:

The core of the network transformer is the magnetic core. The selection of the magnetic core is very particular. Manufacturers choose magnetic cores of different materials according to different uses.

For 10M network transformer:

When in use, the operating frequency band is not very wide, only 10MHZ, and there is no DC current passing through the coil in the use circuit, so there is no need to consider the DC saturation problem of the core material. Therefore, choosing a magnetic core made of 5000u or 7000u material can meet the requirements.

For 100/1000M network transformer:

When in use, the operating frequency band is wide, and there is DC current passing through the coil in the use circuit, so the saturation problem of the core material must be considered. When the core material is not resistant to DC BIAS, when DC current flows through the coil, the core will enter a saturated state; when the core material drops significantly after adding DC BIAS, the RT index (pulse rising edge time) of the transformer ) will increase, and the increase in RT may cause problems such as packet loss during transmission and disconnection when working at full load.

Interface transformer for T1/E1:

Under normal circumstances, the T1/E1 interface transformer requires a high inductance, and 10000u core material is generally used. However, when selecting 10000u core material, you must pay attention to the frequency response issue. As we all know, when changing current passes through the coil, changing magnetic lines of force will be produced in the magnetic core loop, and the N and S poles of the magnetic domains inside the magnetic core will change according to the direction of the current flowing through the coil. When the frequency of the current passing through the coil is higher, the rotation speed of the magnetic domain N and S poles is faster. Due to problems with the core material itself, many magnetic domains inside the core cannot keep up with the rotation and actually enter a state of magnetic saturation.

ADSL transformers generally use mirror-surface, air-gap high magnetic permeability cores. First of all, the high magnetic permeability core of the mirror can reduce the THD value, thereby increasing the transmission distance. Secondly, opening an air gap on the center column of the magnetic core is mainly to prevent the magnetic core from entering a magnetic saturation state. However, during the process of opening the air gap, we must pay attention to the fact that the two surfaces of the air gap are as parallel as possible. When the two surfaces of the air gap are not parallel, the air gap distances at each point are not equal, and the air gap distances at each point are not equal. If not equal, then the magnetic resistance of each point of the magnetic circuit is not equal, which will cause uneven distribution of magnetic lines of force on the cross section of the magnetic circuit, which will reduce the inductance and increase the loss during operation.

Tags:

Enameled Wire Copper wire Aluminum wire Enamelled wire Aluminum Winding Wire Magnet wire Modified polyester Round copper wire Heat resistance Enameled aluminum wire