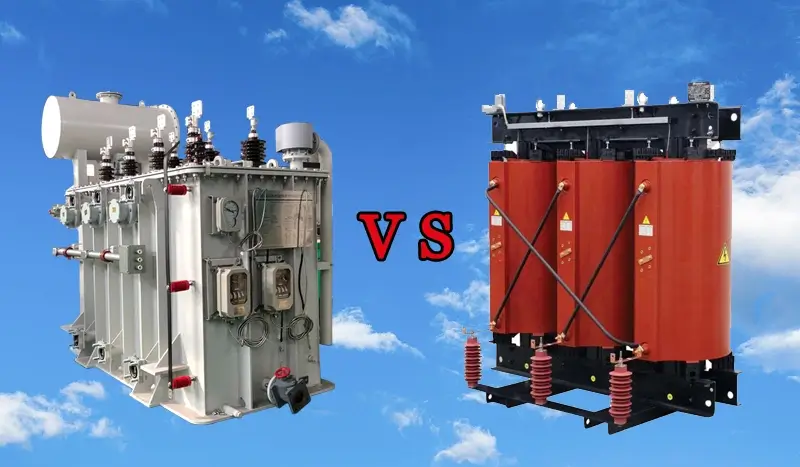

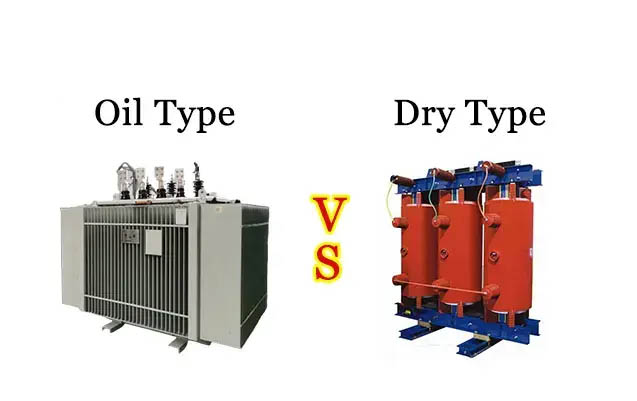

Dry-type transformers and oil-type transformers are two common types of transformers used in electrical power distribution systems. They differ primarily in the cooling and insulation methods employed.

Cooling Method:

Dry-type Transformer: These transformers use air as the cooling medium. They rely on natural air circulation or forced air circulation using fans to dissipate heat generated during operation. The windings and core are encapsulated in epoxy resin or some other suitable solid insulation material, which protects them from the environment.

Oil-type Transformer: In oil-type transformers, mineral oil or synthetic oil is used as the cooling and insulation medium. The windings and core are submerged in oil, which efficiently dissipates heat generated during operation. The oil acts as a coolant and also provides insulation between the windings and core.

Insulation:

Dry-type Transformer: Dry-type transformers use solid insulation materials such as epoxy resin, polyester, or varnish to insulate the windings and core. These materials are non-flammable and environmentally friendly.

Oil-type Transformer: Oil-type transformers use oil as both a coolant and an insulation medium. The oil provides excellent insulation properties and helps to dissipate heat effectively. However, the oil used in these transformers can be flammable and poses environmental risks if it leaks or spills.

Environment and Safety:

Dry-type Transformer: Dry-type transformers are often preferred in indoor applications or locations where fire safety and environmental concerns are paramount. Since they do not use oil, there is no risk of oil leakage or fire hazards associated with oil-filled equipment. Additionally, dry-type transformers do not require regular maintenance of oil levels.

Oil-type Transformer: Oil-type transformers are commonly used in outdoor applications or indoor applications where large power ratings are required. While they provide efficient cooling and insulation, there are concerns regarding oil leakage, fire hazards, and environmental impact. Regular maintenance is required to monitor oil levels, ensure proper insulation, and prevent oil leaks.

Applications:

Dry-type Transformer: Dry-type transformers are suitable for indoor applications such as commercial buildings, hospitals, schools, and underground substations. They are also preferred in areas where fire safety and environmental regulations are strict.

Oil-type Transformer: Oil-type transformers are commonly used in outdoor installations such as utility substations, industrial plants, and power generation facilities. They are also used in applications requiring high power ratings and where space constraints are not a concern.

Tags:

Enameled Wire Copper wire Aluminum wire Enamelled wire Aluminum Winding Wire Magnet wire Modified polyester Round copper wire Heat resistance Enameled aluminum wire